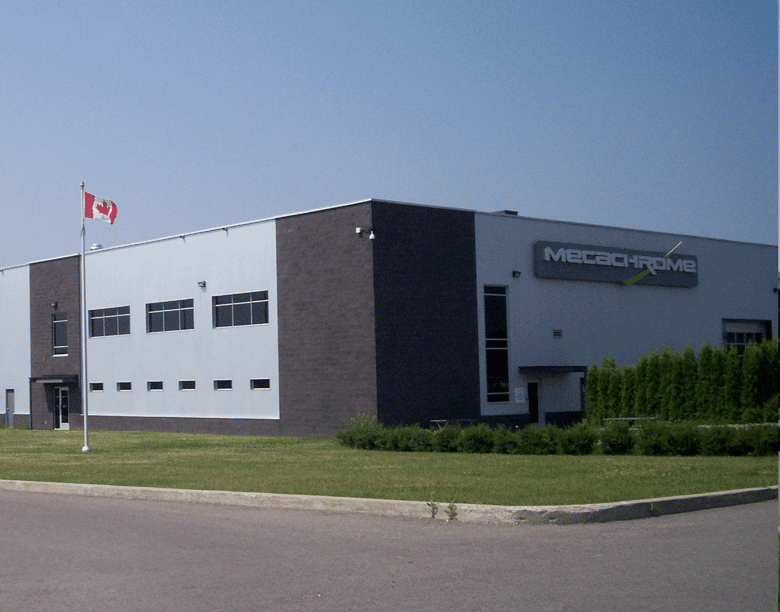

Annecy

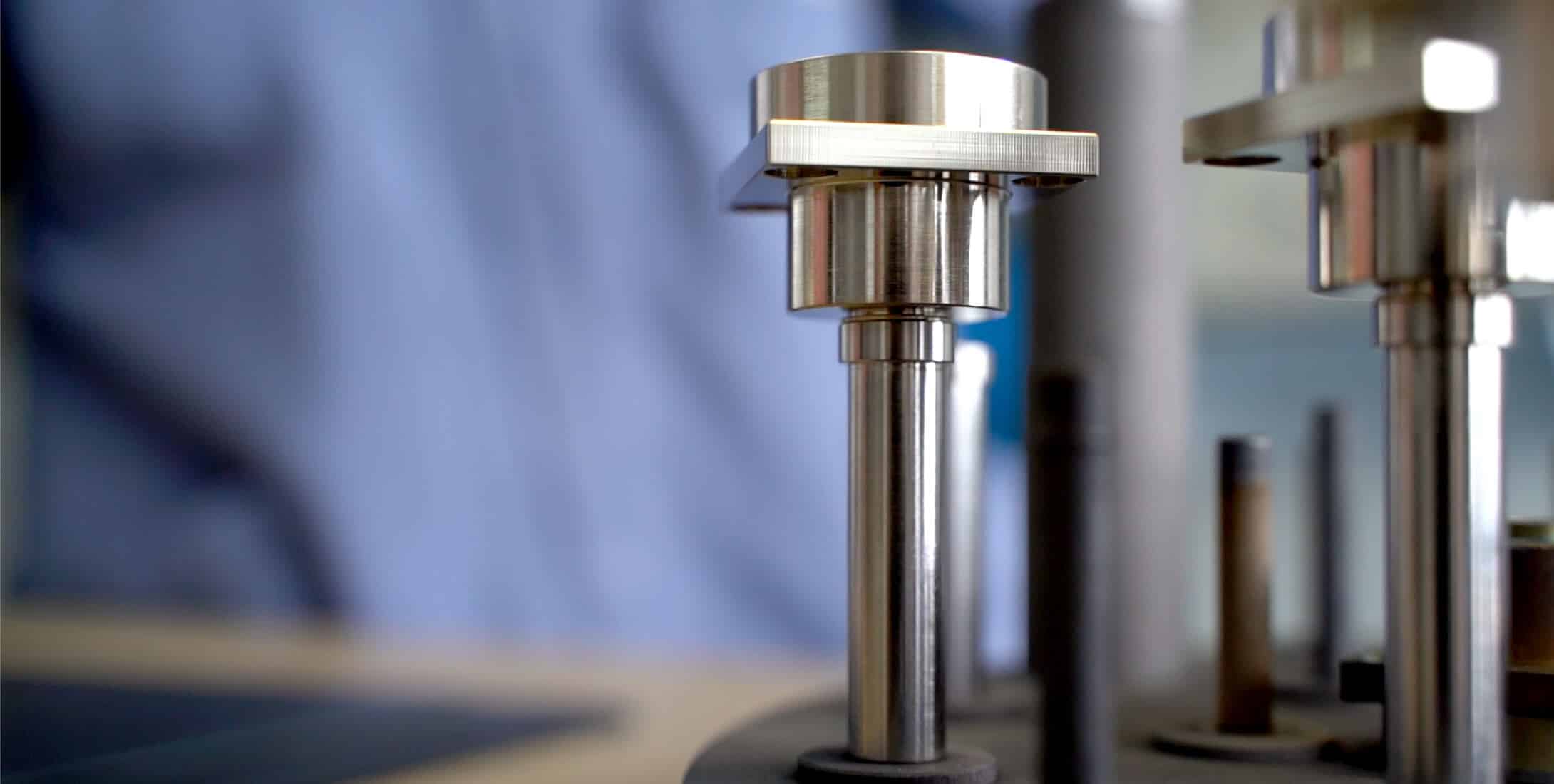

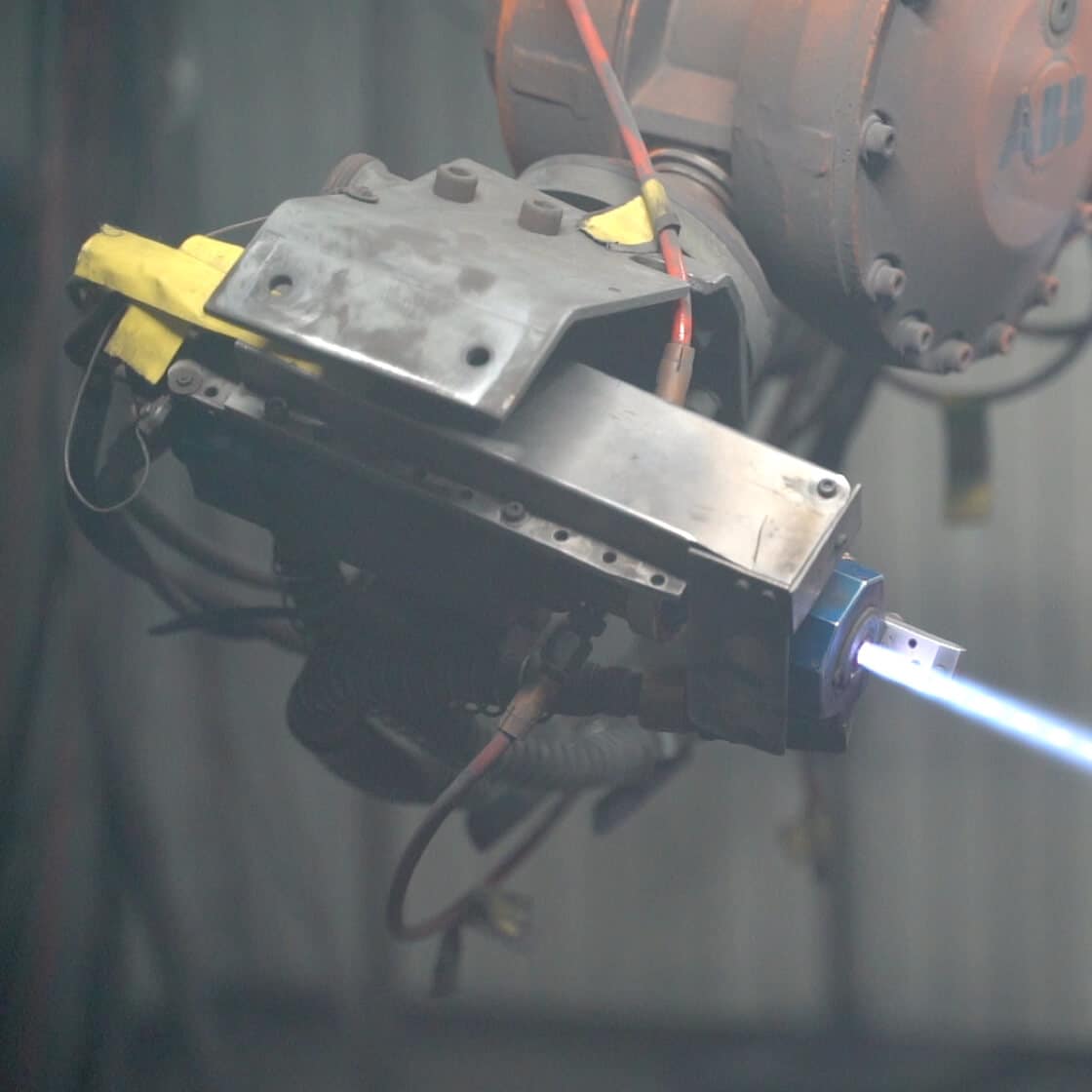

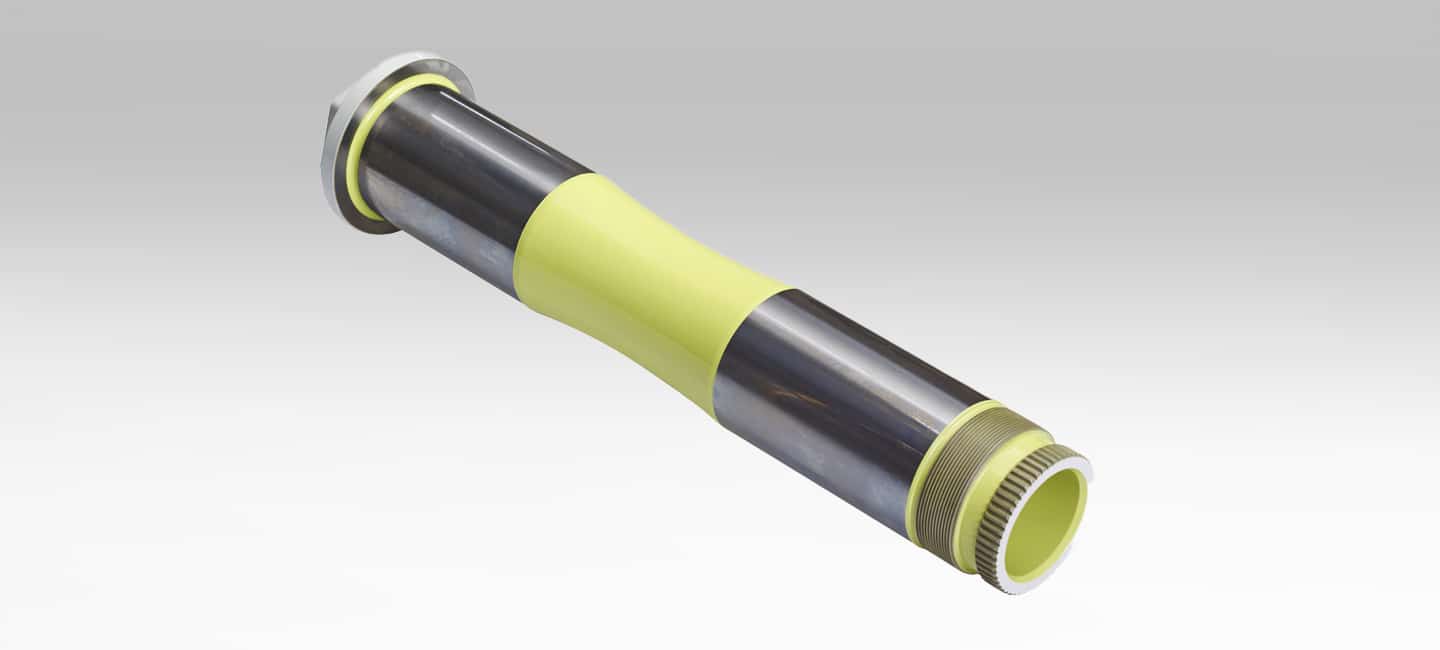

The Mecachrome Annecy site is the group's spearhead in special high performance processes: thermal spray coating for finishing and strengthening of sensitive components (High Velocity Oxygen Fuel - HVOF and Plasma), vacuum braising and electron-beam welding.

Key data

Landmark dates: 1957 (SICN) / 2004 (GEMMA group HITIM) / 2021 MECACHROME

Sectors of special interest: aeronautics, defense, energy (oil, nuclear)

Specialties:

- Precision machining

- Thermal spraying (HVOF and Plasma)

- Vacuum braising

- Electron-beam welding (EBW)

- Graphite machining

Customers: Safran, Safran Landing System, Lynred, CEA, Thales, Schlumberger, Dassault Aviation

Employees: 50

Surface area: 5,000 m²

Industrial capacity (key technologies):

- Turning

- Milling

- Grinding

- Fitting

- Cylindrical honing

- Inspection

- NDT: magnetic particle inspection penetrant

- Attaque mital (NADCAP)

- Analysis laboratory

Products Manufactured

Created in 1957, a subsidiary of SICN devoted to the nuclear sector, the site became a subsidiary of COGEMA and then of AREVA. GEMMA became independent in 2004, and has progressively moved towards precision engineering and aeronautics.

In summer 2021, the Annecy site became part of MECACHROME and completes the group’s global offer with its leading-edge technologies.