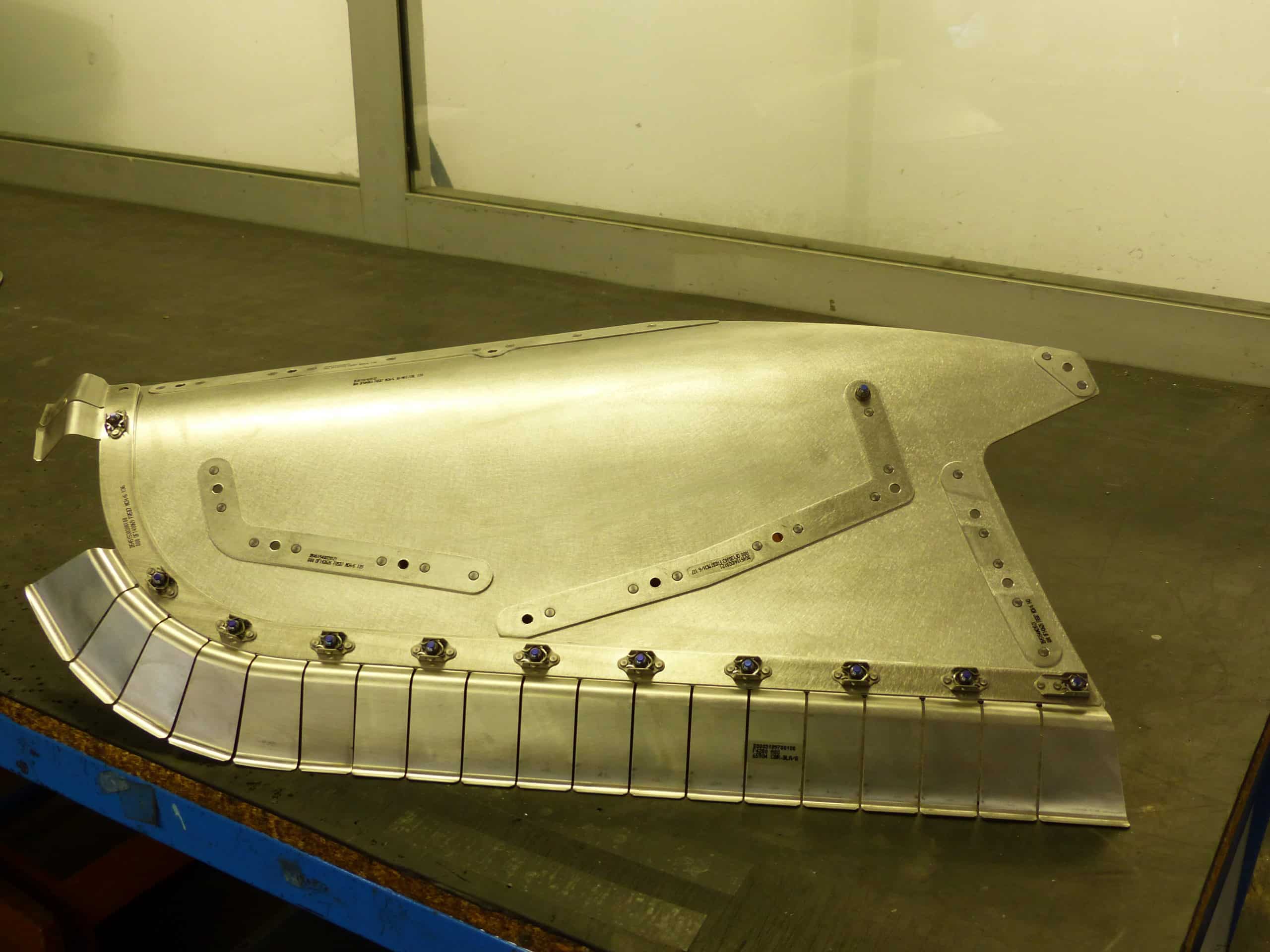

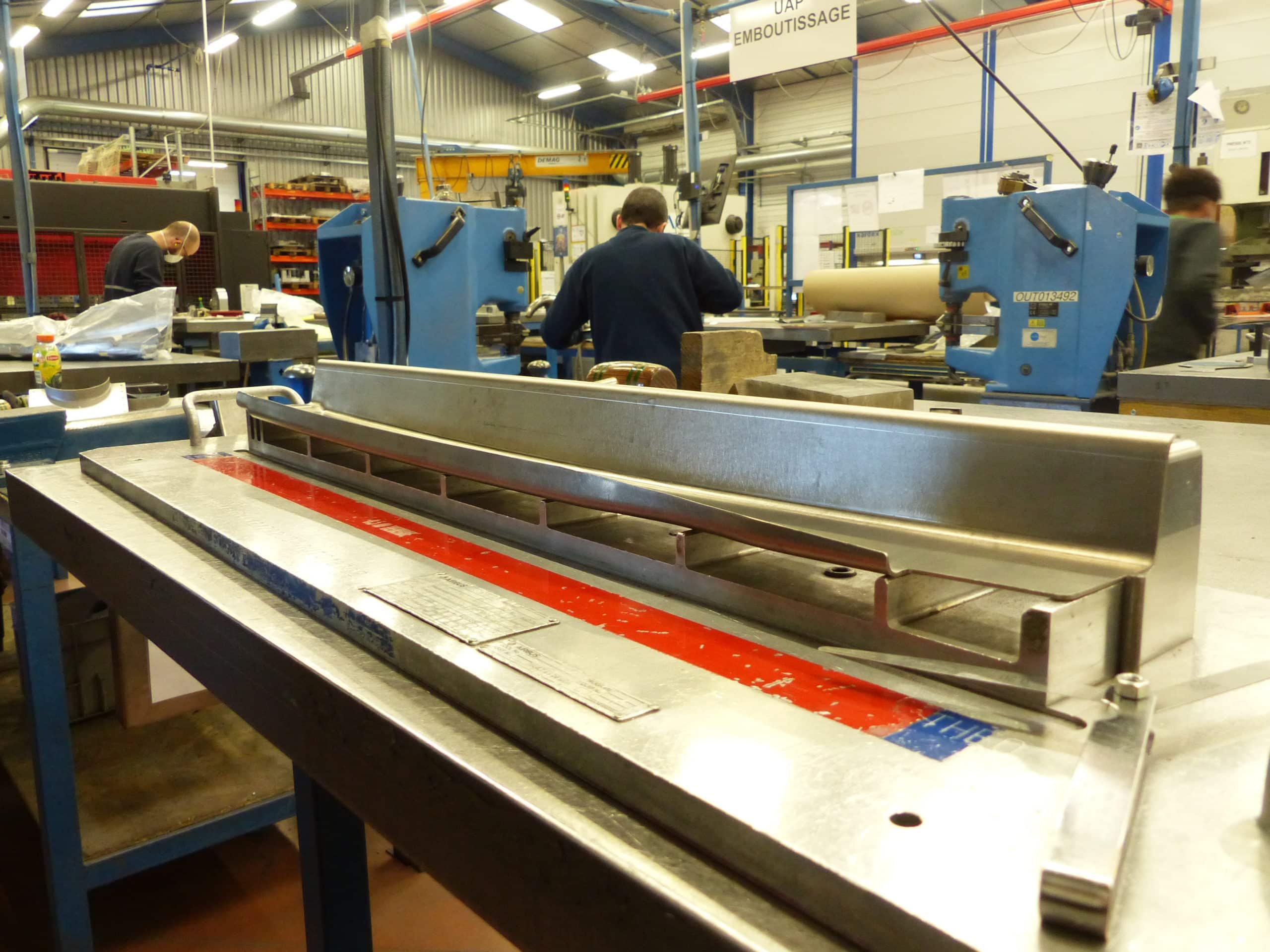

Sheet metal working and boiler making

Mecachrome's sheet metal working and boiler making activities offer a full range of production of aerostructure elements based on know-how in product industrialization, manufacture and assembly of sheet metal and boiler making parts and assemblies in both light alloys and hard metals.

Industrialization includes design, technical studies, development and manufacture of the tools and the methods associated with sheet metal working and boiler making activities and structural assembly.

Industrialization includes design, technical studies, development and manufacture of the tools and the methods associated with sheet metal working and boiler making activities and structural assembly.

Different skill sectors:

- Industrialization

- Manufacture of formed parts and structural assembly

Raw Material:

- Aluminium Alloys

- Hard Metals (Titanium, Stainless Steel, Steel, Inconel)

Key technologies and processes:

- Trimming: Laser cutting, Punching, Metal trimming by machining

- Stamping

- Folding

- Boiler making, recovery

- Heat Treatment (Nadcap Accredited)

- Surface treatment: Chromating and Painting

- Structural assembly

Our added value for Customers:

- A skill center in Launaguet, in the suburbs of Toulouse close to customers, for industrialization.

- “Best cost” sites to offer our customers a competitive proposal, for mass production.

- A competitive offer and “derisking” for production thanks to a mixed environment: France and Best Cost Countries.